- Kinetic Group launches a state-of-the-art battery manufacturing facility in Ahmednagar, targeting India’s growing EV market.

- The facility aims to produce 60,000 advanced LFP and NMC battery packs annually, focusing on two- and three-wheeler EVs.

- A Rs. 50 crore investment underscores a move toward cleaner, sustainable transportation through cutting-edge battery technology.

- Batteries incorporate a smart Battery Management System and IoT-enhanced precision, ensuring efficiency, longevity, and high safety standards.

- Kinetic plans to supply batteries to various OEMs, supporting India’s EV industry growth projected at US$18.319 billion by 2029.

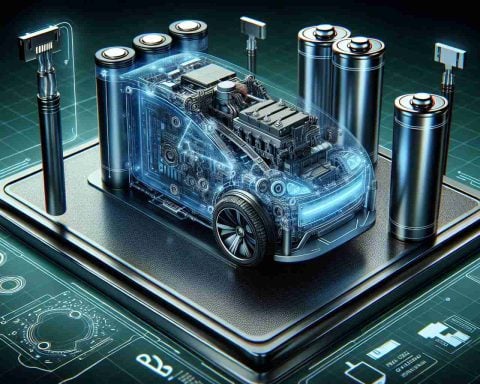

Under the vast sky of Ahmednagar, a beacon of innovation rises—a new, state-of-the-art battery manufacturing facility by the esteemed Kinetic Group. This sprawling center hums with the ambition of producing 60,000 high-performance battery packs annually, marking the group’s electrifying leap into the burgeoning electric vehicle (EV) market.

Imagine rows of gleaming production lines, each meticulously crafted to churn out advanced LFP and NMC battery types designed for India’s swiftly growing two- and three-wheeler EV segment. With a hefty investment of Rs. 50 crore, this facility promises not just progress, but a revolution—a thrust toward cleaner, efficient, and sustainable transportation.

Kinetic’s vision doesn’t stop at supporting its own brands. These batteries, crafted with durable, recyclable materials, are set to power a future fleet from various original equipment manufacturers (OEMs)—a testament to their broad appeal and reliability. As India’s EV industry accelerates towards an estimated market value of US$18.319 billion by 2029, the facility stands poised to meet and propel this rapid growth.

The essence of Kinetic’s batteries lies in their cutting-edge technology. Using the latest LFP technology, the units not only promise peak performance in extreme conditions but also boast a smart Battery Management System (BMS) to maximize efficiency and longevity. Meanwhile, their NMC counterparts promise robust energy density, ensuring longer rides between charges.

Automated production lines imbued with IoT-enhanced precision, alongside rigorous stage-wise inspections, ensure each battery meets the high safety and quality standards. This facility isn’t just about production—it’s a testament to Kinetic Group’s commitment to safety, sustainability, and self-reliance, strengthened by the Make in India initiative.

The horizons for India’s EV scene are expanding, and with Kinetic Group’s bold move, the journey toward an eco-friendly tomorrow accelerates, promising a brighter, greener future for all.

Revolutionary Dawn: Inside Kinetic Group’s Advanced EV Battery Facility in Ahmednagar

How-To Steps & Life Hacks: Maximizing Battery Life

1. Regularly Update the BMS: Ensure that the Battery Management System (BMS) is up-to-date. Updates often contain improvements that enhance performance and safety.

2. Optimal Charging Practices: Avoid overcharging. Charging up to 80% can extend the life of the battery, as Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) batteries perform best when not fully charged or discharged.

3. Keep Cool: Extreme temperatures can degrade battery efficiency. Store vehicles in shaded or covered areas when not in use.

4. Routine Inspection: Periodically checking connectors and physical integrity can help catch issues early.

Real-World Use Cases

– Urban Commuting: The durability and efficiency of LFP and NMC batteries make them ideal for the daily commute, handling the start-stop traffic of city life with ease.

– Logistics: The high energy density of NMC batteries supports longer distances, beneficial for last-mile delivery businesses.

– Ride Sharing: Companies can leverage these batteries for fleet services, optimizing costs with reliable and low-maintenance power sources.

Market Forecasts & Industry Trends

India’s electric vehicle market is expected to grow dramatically, pushed by favorable government policies and a rising demand for sustainable transportation. The Kinetic Group’s facility is geared to capitalize on this trend:

– Growth Projection: The market is anticipated to reach US$18.319 billion by 2029 (Invest India).

– Two-Wheelers Rising: The segment represents a major portion of EV adoption in India, with battery efficiency playing a crucial role.

Reviews & Comparisons

– LFP vs. NMC:

– LFP: Known for safety and longevity; ideal for high-frequency use cases.

– NMC: Offers higher energy density, allowing for longer-range travel.

Controversies & Limitations

– Material Sourcing: Ethical concerns surround cobalt sourcing for NMC batteries. Kinetic’s commitment to sustainable sourcing practices is crucial to addressing these concerns.

– Recycling Challenges: Although recyclable materials are used, establishing effective recycling programs will be critical.

Features, Specs & Pricing

– LFP Batteries: Cost-effective, excellent thermal stability, longer cycle life.

– NMC Batteries: Higher upfront costs due to higher energy density and longer range.

Security & Sustainability

– IoT-Enhanced Precision: Automation reduces human error, enhancing quality and safety standards.

– Sustainable Manufacturing: Commitment to the Make in India initiative and using recyclable materials affirms a focus on environmental consciousness.

Pros & Cons Overview

Pros:

– Advanced BMS for enhanced battery life.

– Supports various EVs, boosting versatility.

– High production capacity ensures supply meets demand.

Cons:

– Initial investment costs may be high for small OEMs.

– Sustainability efforts must scale with production.

Insights & Predictions

– Kinetic’s facility could lead to reduced battery costs over time due to economies of scale.

– Enhanced export opportunities as global demand for reliable battery packs grows.

Conclusion: Actionable Recommendations

For businesses and consumers aiming to harness the potential of Kinetic’s batteries:

1. Stay Informed: Regularly update BMS software to optimize battery performance.

2. Prioritize Maintenance: Follow best practices for longevity and efficiency.

3. Consider EV Investments: Leverage financial incentives and lower operational costs to transition to electric vehicles.

By understanding these facets of Kinetic Group’s advancements and the broader market, stakeholders can make informed decisions aligned with future trends.

For more insights into India’s burgeoning electric vehicle landscape, visit Invest India.