- Altilium’s EcoCathode technology achieves over 97% lithium and 99% graphite recovery from end-of-life LFP batteries.

- The company aims to lead the UK’s circular battery economy amid rising demand for LFP batteries.

- Altilium also recycles Nickel Manganese Cobalt (NMC) batteries, supporting a sustainable battery supply chain.

- The new recycling plant in Plymouth processes one EV battery daily, with plans for increased capacity in Teesside.

- This innovation plays a crucial role in promoting responsible recycling and advancing environmental goals for the automotive industry.

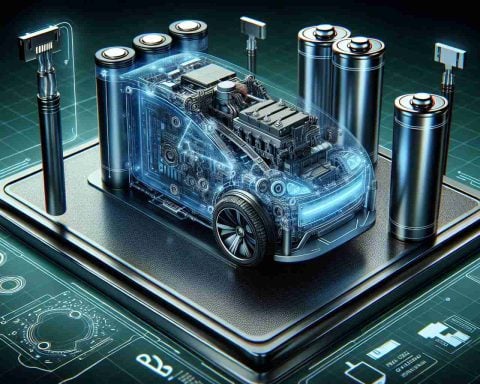

In a groundbreaking move for sustainability, Altilium, a UK-based innovator, is transforming the future of electric vehicle (EV) battery recycling. The company has unveiled its revolutionary EcoCathode technology, which recycles end-of-life Lithium Iron Phosphate (LFP) batteries, achieving an astonishing recovery rate of over 97% lithium and 99% graphite.

With the demand for LFP batteries expected to soar, Altilium is seizing the opportunity to lead the charge in the UK’s circular battery economy. Their advanced methods allow for efficient extraction of these valuable components, bolstering the business model for battery recycling while aiding automotive manufacturers in meeting their sustainability goals.

Dr. Christian Marston, COO of Altilium, highlights the critical role their technology plays in addressing the growing need for responsible recycling solutions. The firm is not just focused on LFP but is also recycling Nickel Manganese Cobalt (NMC) batteries from major automotive OEMs, enhancing the nation’s battery supply chain for a greener transport sector.

Altilium’s new recycling plant in Plymouth is particularly impressive, capable of processing the equivalent of one EV battery per day and poised to scale up with plans for a hub in Teesside to handle scraps from over 150,000 EVs per year.

The key takeaway? With Altilium leading the way, the future of recycling EV batteries is not just bright – it’s sustainable and vital for our transition to cleaner transportation. This technological leap not only preserves resources but also paves the way for a greener planet.

Unlocking the Future: Altilium’s Game-Changing EcoCathode Technology for EV Battery Recycling

Introduction

In a significant advancement for sustainability within the automotive industry, Altilium is making strides with its innovative EcoCathode technology. This new recycling method not only tackles the challenges associated with end-of-life Lithium Iron Phosphate (LFP) batteries but also establishes a model for a circular economy in battery production.

Key Innovations

1. High Recovery Rates: Altilium’s technology boasts recovery rates of over 97% for lithium and 99% for graphite, effectively reclaiming these critical resources for reuse in the battery manufacturing process.

2. Comprehensive Recycling: Apart from LFP batteries, Altilium is addressing the recycling of Nickel Manganese Cobalt (NMC) batteries, expanding its impact across various EV manufacturers.

3. Scalable Operations: The newly established recycling plant in Plymouth can process the equivalent of one complete EV battery per day. Plans for a larger facility in Teesside aim to support the recycling of components from over 150,000 EVs annually, showcasing the scalability of Altilium’s operations.

Market Insights and Trends

– Demand Surge: The acceleration in electric vehicle production will inevitably increase demand for effective recycling solutions, positioning Altilium at the forefront of this emerging market.

– Regulatory Environment: Stricter environmental regulations are driving automotive manufacturers to seek sustainable practices, enhancing Altilium’s value proposition as a key player in the battery recycling landscape.

Pros and Cons

Pros:

– Significant recovery rates enhance resource efficiency.

– Contributes to green technology and sustainable practices.

– Supports the growing demand for EVs by ensuring a steady supply of recycled materials.

Cons:

– Initial capital expenditure to set up recycling plants can be significant.

– Requires continuous advancements to keep up with evolving battery technologies.

Limitations and Challenges

While Altilium’s EcoCathode technology demonstrates impressive capabilities, there are inherent challenges:

– The initial cost of setting up advanced recycling facilities can be prohibitive.

– Continuous innovation is required to adapt to the rapid evolution of battery chemistries.

Pricing and Market Forecast

Altilium’s services are likely to align with market demands, offering competitive pricing as the recycling industry matures. Analysts predict a growing value in the battery recycling sector, expected to reach billions in the next decade, driven by increased EV adoption and sustainability goals.

Future Predictions

The landscape for EV battery recycling is on the brink of transformation. With technological advancements from companies like Altilium, recycling processes will become more efficient and vital in achieving global sustainability targets, creating opportunities for both economic growth and environmental benefits.

Frequently Asked Questions

1. How does EcoCathode technology work?

EcoCathode technology employs innovative chemical processes to efficiently extract lithium and graphite from used batteries, ensuring high recovery rates.

2. What types of batteries can Altilium recycle?

Altilium primarily focuses on Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) batteries, catering to a wide range of electric vehicle manufacturers.

3. Why is battery recycling important?

Battery recycling plays a crucial role in conserving the earth’s resources, reducing pollution, and ensuring a sustainable supply of materials required for electric vehicles, thus contributing to a greener future.

For more information on sustainability and innovative recycling methods, visit Altilium.